Blog

What is CNC Punch Cutting?

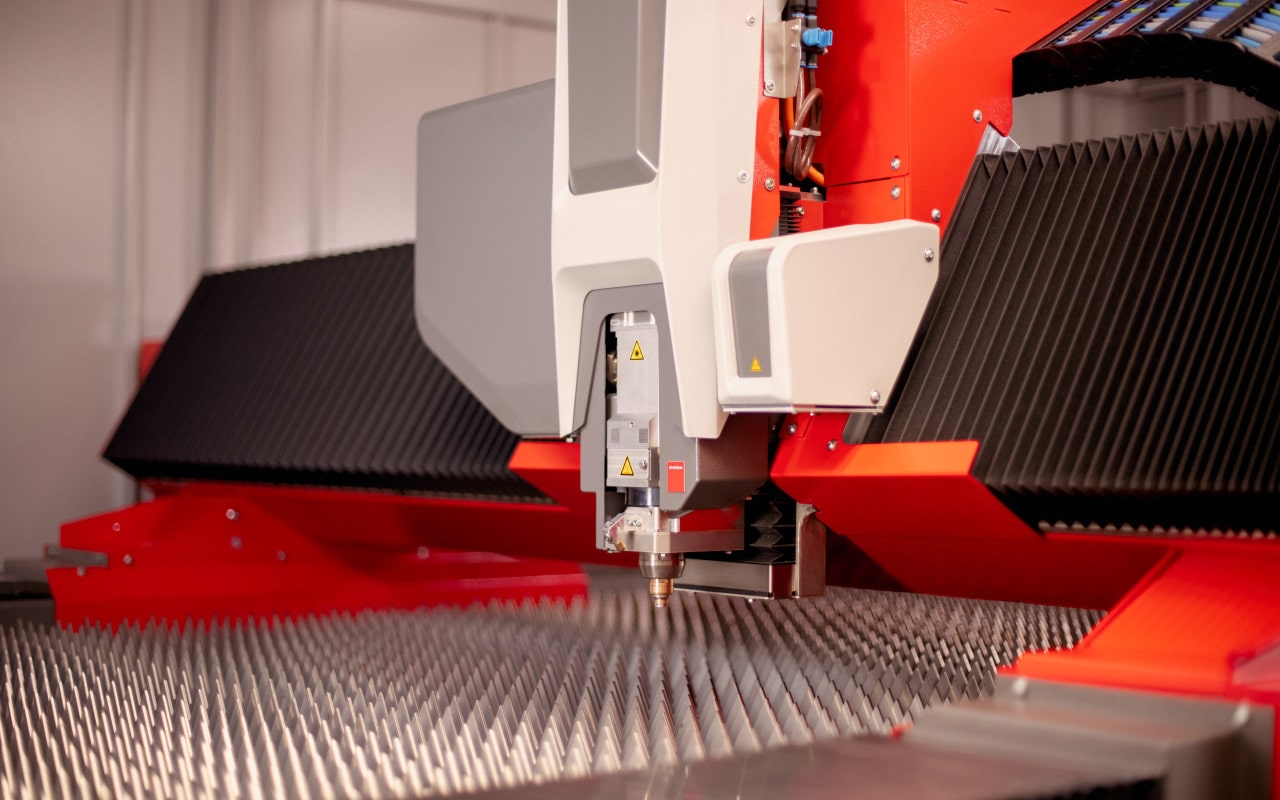

CNC punch cutting is a manufacturing process that uses a computer numerical control (CNC) system to guide a punch tool to cut holes or other shapes into a piece of material, such as sheet metal or plastic.

The punch tool is typically a cylindrical tool with a sharp edge on one end, which is guided by the CNC system to follow a precise set of instructions or a pre-programmed design to cut the material into the desired shape.

CNC punch cutting is a highly accurate and efficient process that allows for the creation of complex and detailed shapes with a high degree of repeatability. The process is commonly used in industries such as manufacturing, automotive, aerospace, and electronics, where precise and accurate holes or other cutouts are required in parts and components.

The CNC punch cutting process typically involves securing the material to be cut onto a worktable, using clamps or other fastening devices to hold it in place. The punch tool is then positioned above the material, and the CNC system is used to guide the tool along the desired path to cut the material. The speed and depth of the punch tool can also be controlled using the CNC system, allowing for precise and accurate cuts. Once the punching is complete, the finished part or component is removed from the worktable and the process is repeated as needed to produce multiple parts or components.