Blog

Applications of Laser Cutting in Various Materials and Custom Design CNC Laser Cutting Products

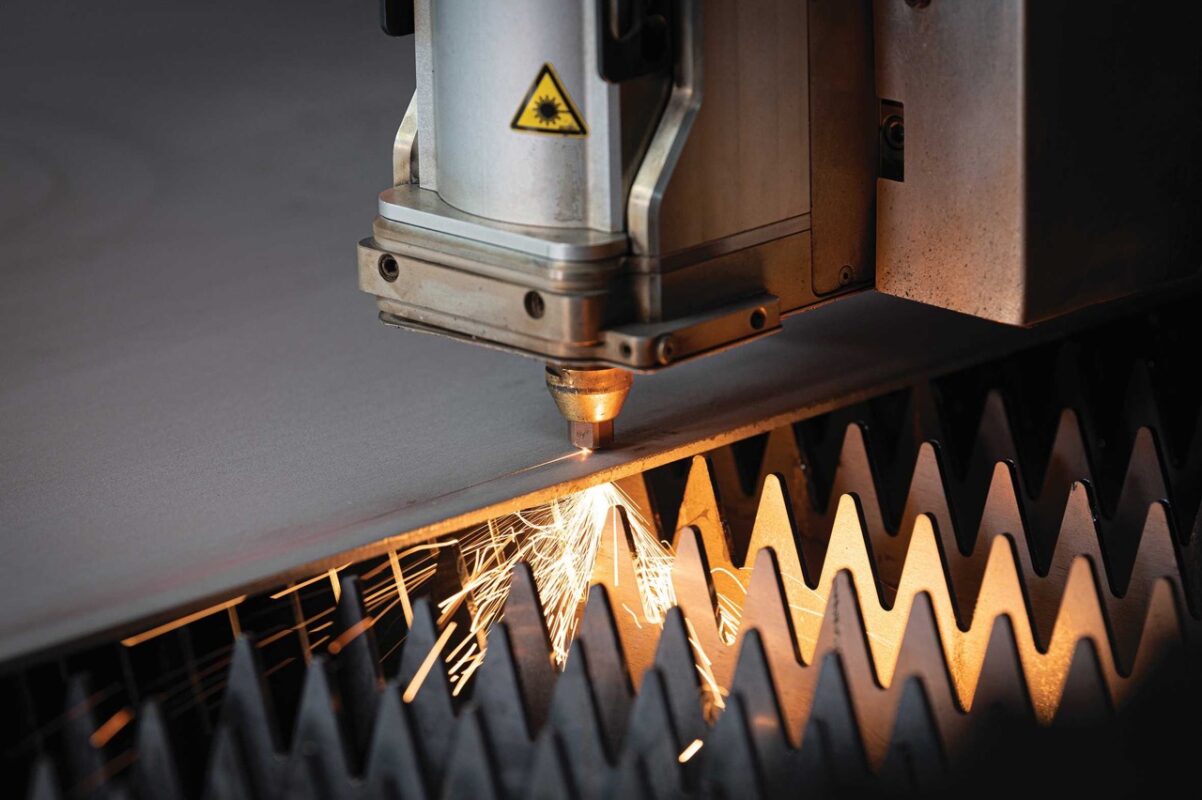

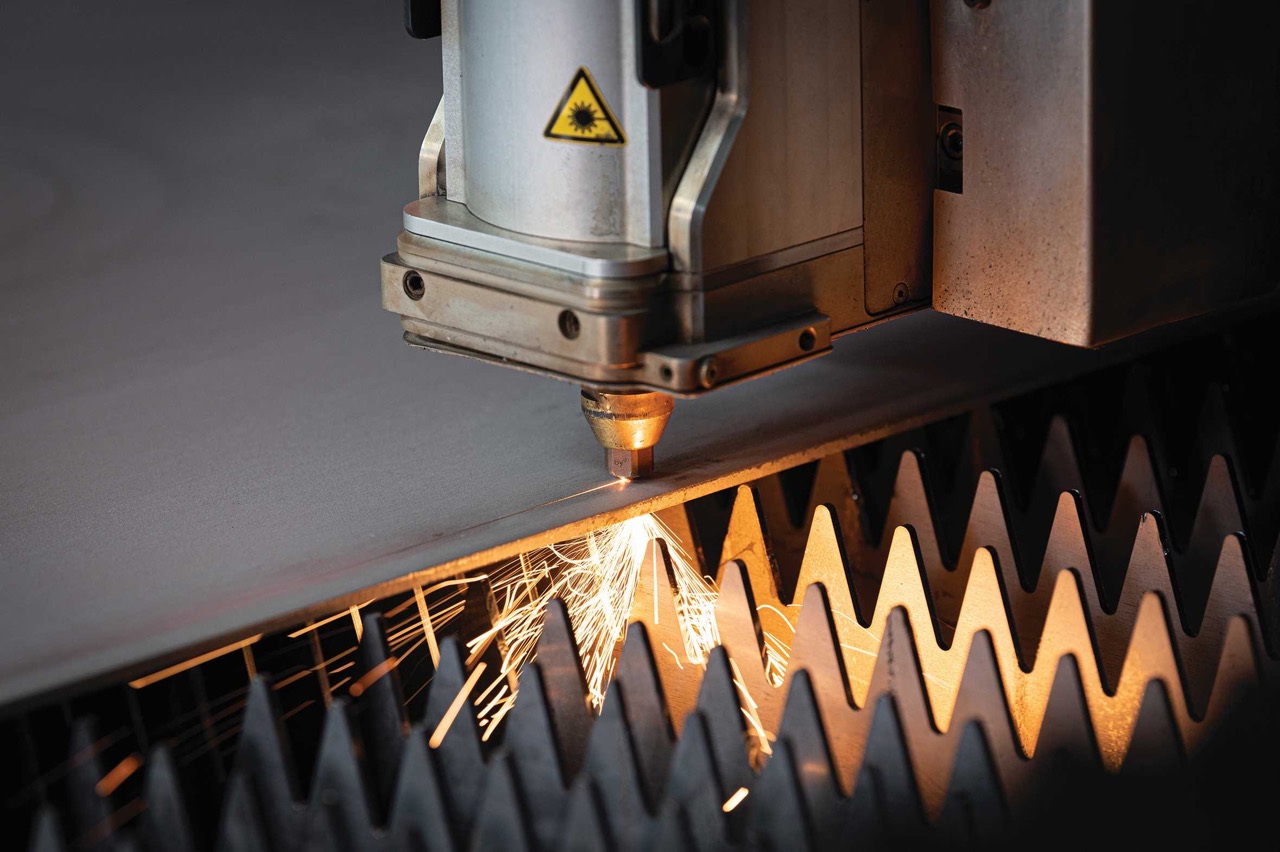

With the advancement of technology, laser cutting applications have revolutionized industries. Laser cutting in different materials not only allows for precise and sharp cuts but also plays a crucial role in producing custom-designed products.

Material Selection and Characteristics

Laser cutting finds its application across a spectrum of materials including metals, wood, plastics, fabrics, and glass, each possessing unique processing methods and characteristics.

1. Metals: Laser cutting is commonly used for materials such as steel, aluminum, and brass. High-intensity laser beams enable precise cutting of metals and facilitate the creation of intricate shapes.

2. Wood: Wood materials are ideal for laser cutting applications in furniture, decor, and packaging industries. The impact of lasers on wood ensures smooth and detailed cuts.

3. Plastics: Materials like polycarbonate, acrylic, and PVC can be cut and engraved using laser cutting techniques. Care should be taken as plastics have a risk of melting during laser processing.

4. Fabrics: Laser cutting plays a significant role in the textile industry for cutting garments, curtains, and upholstery. It allows for precise cutting and detailing without the fabric burning.

5. Glass: Laser processing of glass minimizes the risk of breakage while facilitating the production of decorative and functional items. Laser cutting can create patterns or perform precise cuts on glass surfaces.

Each material comes with distinct thicknesses, densities, and properties, making material selection a crucial aspect in laser cutting applications. Material characteristics influence the type of laser used, ensuring optimal results and efficiency in the cutting process.

Custom Design CNC Laser Cutting Products

The integration of Computer Numerical Control (CNC) technology with laser cutting has enabled the creation of custom-designed products that cater to diverse needs across industries.

1. Prototyping: CNC laser cutting allows for the rapid creation of prototypes in various materials. It offers flexibility in design iterations and helps in evaluating product concepts before full-scale production.

2. Custom Signage and Branding: Laser-cut signage provides precision in creating custom logos and branding materials. It offers versatility in design and ensures a polished finish for professional presentations.

3. Art and Décor: CNC laser cutting has revolutionized the art and decor industry by enabling intricate designs on materials like wood, metal, and acrylic. It allows artists and designers to explore complex designs with precision.

4. Jewelry and Fashion: In the fashion and jewelry sector, CNC laser cutting aids in creating unique, intricate patterns on fabrics, leather, and metals, offering personalized and trendy designs.

5.Architectural Models: CNC laser cutting finds applications in architecture for creating intricate models and detailed representations of building designs with high precision and accuracy.

Laser cutting technologies continue to transform manufacturing processes across industries. The ability to work with diverse materials and create custom-designed products through CNC laser cutting has expanded possibilities for innovation and creativity, driving advancements in product development and design.