Blog

The Sustainability and Environmental Impacts of CNC Laser Cutting

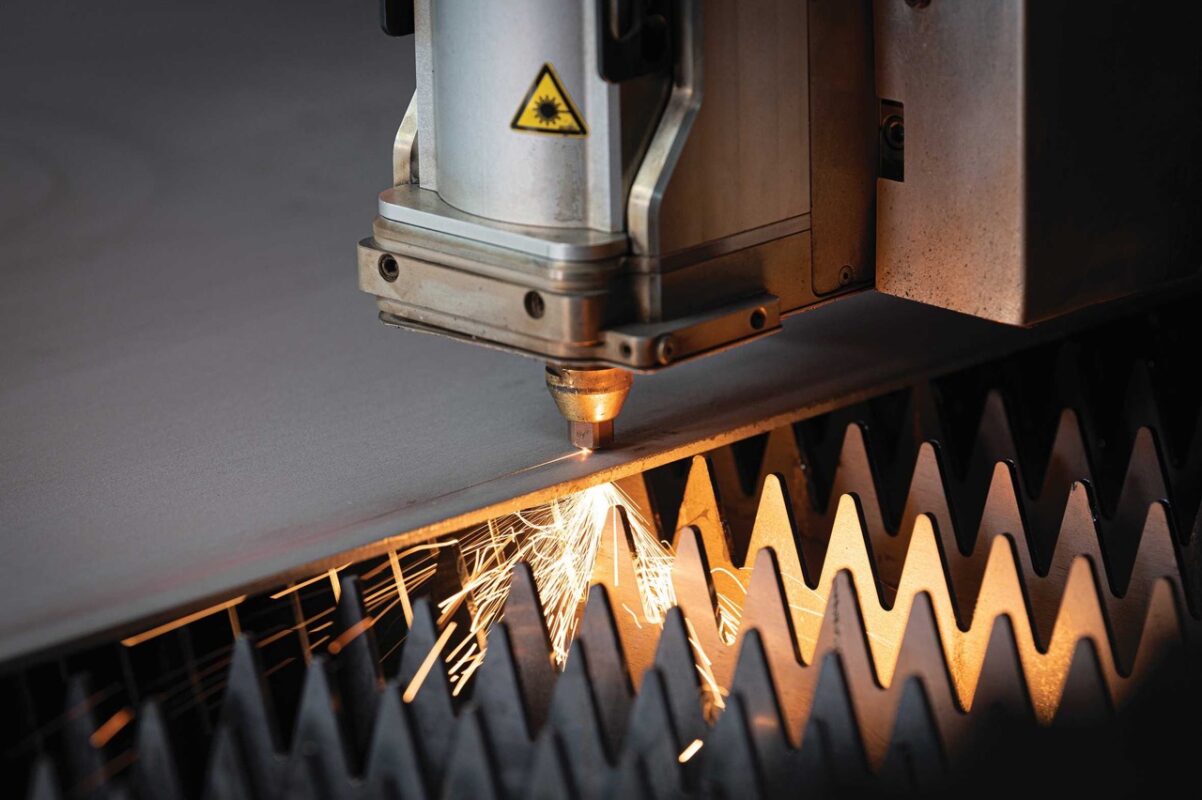

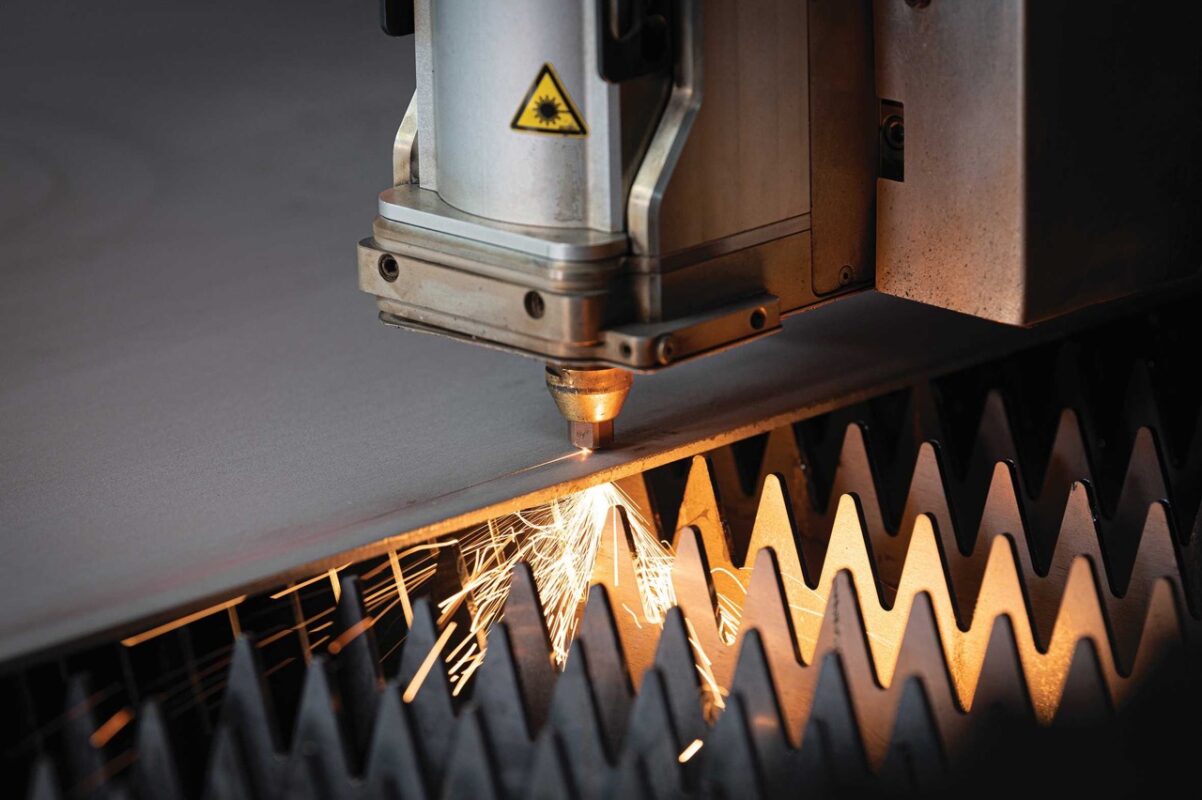

CNC laser cutting has become a significant technology in modern manufacturing industries. Used in various sectors, this method facilitates the precise and rapid cutting of materials, optimizing production processes. However, the environmental impacts and sustainability implications of this technology are increasingly drawing attention.

Sustainability stands as a focal point in today’s manufacturing industry. To comprehend the environmental impacts of CNC laser cutting, it’s essential to review both the benefits and environmental risks associated with this technology.

One advantage offered by CNC laser cutting is its precision in the cutting process, allowing materials to be cut into specific dimensions and shapes. This reduces material wastage, enhancing production efficiency compared to traditional cutting methods. It results in less material loss.

Furthermore, the laser technology utilized in CNC cutting consumes less energy compared to other cutting methods. This helps reduce the carbon footprint, a fundamental aspect of sustainable manufacturing processes. Lower energy consumption is a cornerstone of sustainable manufacturing, and CNC laser cutting contributes positively in this aspect.

However, the environmental impacts of CNC laser cutting cannot be disregarded. The use of this technology may generate certain hazardous waste materials if not properly managed. Inadequate handling of the waste generated during laser cutting can pose a risk to the environment. Special procedures and facilities might be necessary for the recycling and proper disposal of these wastes.

Additionally, the laser technology itself might have environmental implications during the production of industrial lasers. Processes such as extraction, processing, and transportation of materials used in manufacturing laser devices can impact environmental resources. Therefore, the environmental effects during the production stage of laser technology should also be taken into account.

The assessment of CNC laser cutting concerning sustainability should encompass factors such as waste management, energy efficiency, and material utilization. Industrial facilities need to enhance waste management strategies while increasing recycling possibilities and seeking innovative methods to conserve energy.

CNC laser cutting technology can enhance efficiency in the manufacturing industry and reduce material wastage. However, its environmental impacts and implications for sustainability must be considered. Industrial facilities should embrace sustainable production principles while utilizing this technology, focusing on their environmental responsibilities. This could increase industrial process efficiency while creating a production environment that causes less harm to the environment.