Blog

What Does CNC Cutting Mean?

CNC cutting refers to the use of computer numerical control (CNC) technology to cut materials, such as metal or plastic, into a specific shape or design.

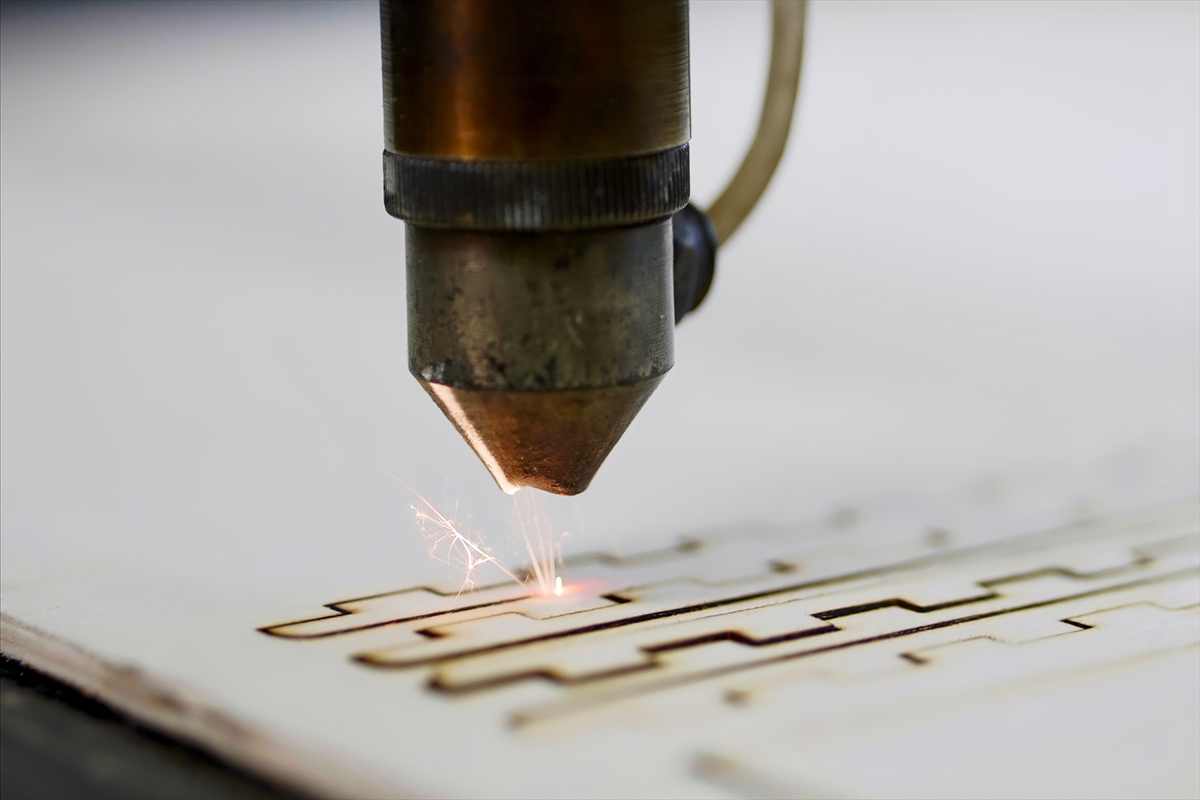

This is typically done using a cutting tool, such as a router or a laser, which is guided by the CNC system to follow a precise set of instructions or a pre-programmed design. CNC cutting is used in a variety of industries, including manufacturing, automotive, aerospace, and electronics, to create high-precision parts and components with a high degree of accuracy and repeatability.

CNC cutting is a common manufacturing process that is used to produce a wide range of parts and components with a high degree of precision and accuracy. The process involves using a cutting tool, such as a router or a laser, which is guided by a computer numerical control (CNC) system to cut materials, such as metal or plastic, into a specific shape or design.

One of the key advantages of CNC cutting is that it allows for the creation of complex and detailed designs with a high level of precision and repeatability. This is because the CNC system is able to follow precise instructions or a pre-programmed design, allowing for consistent results every time. Additionally, CNC cutting can be used to cut a wide variety of materials, including metals, plastics, composites, and even wood, making it a versatile manufacturing process.

CNC cutting is commonly used in industries such as manufacturing, automotive, aerospace, and electronics, where precise and accurate parts and components are required. The process is also used in the creation of prototypes, as well as for custom or one-off pieces, such as in the creation of art or signage. Overall, CNC cutting is an important manufacturing process that allows for the production of high-quality parts and components with a high degree of precision and repeatability.